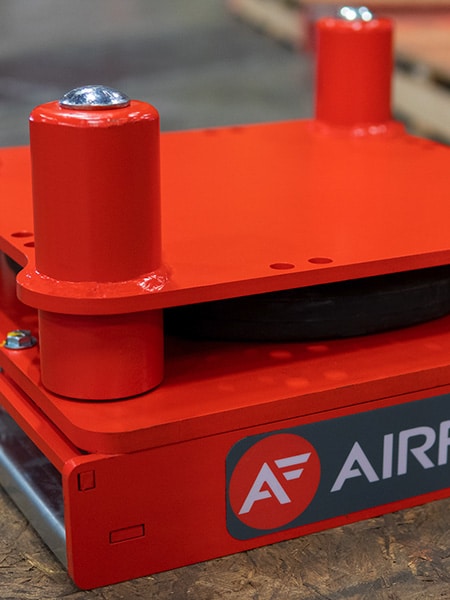

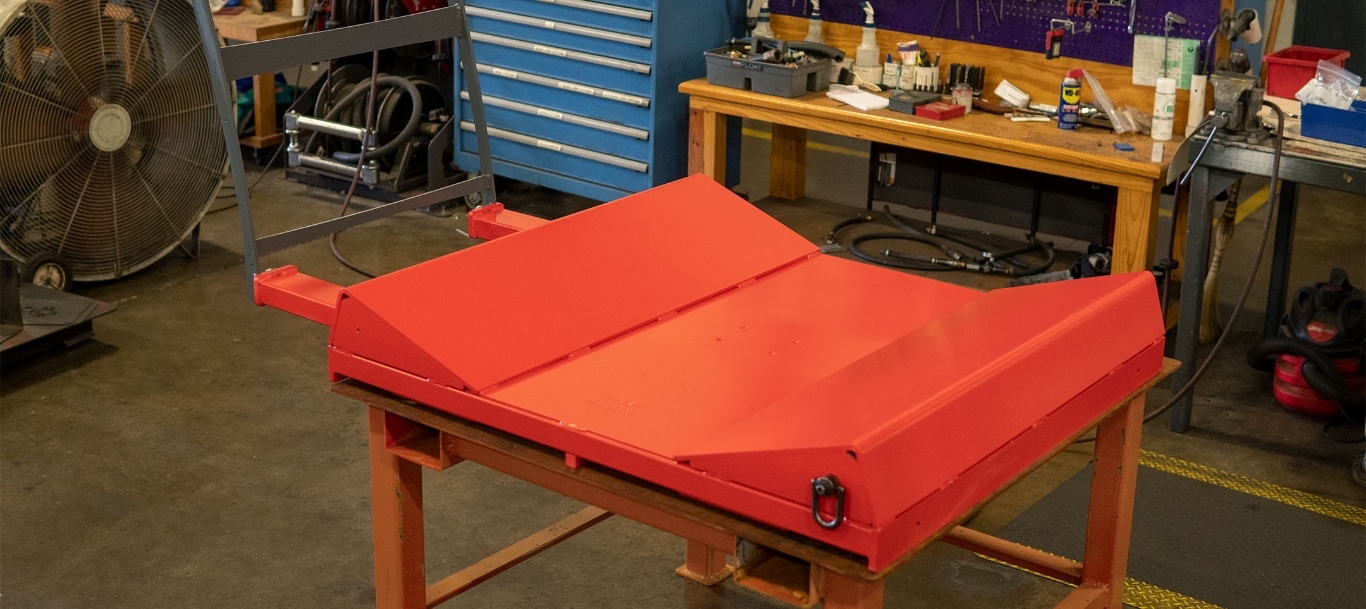

Air Platform with Roll Cradle

Features

on Quality

Maintenance

has ripped due to some debris on the floor. We’ve designed our Skids to be easy to repair with slide-out trays to replace the Air Caster without removing the Roll/Load- leading to minimal downtime and a quick turnaround to get back to moving heavy loads.

Chocks

We exist to create material handling solutions for moving and positioning heavy and difficult to position loads with low friction, omnidirectional movement. The Air Caster is a pneumatic device that forms a lubricating film of air between the load and floor surface, similar in principle to a hovercraft or an air hockey table. We provide material handling products and solutions for heavy loads when frictionless, omnidirectional movement is critical.

Many people believe a perfect floor, polished to a mirror finish, is required in order to use air caster technology. Most Airfloat equipment is designed to operate on machine-troweled concrete. However, the floor does need to be reasonably flat and level. Call 800-888-0018 today to speak with an application engineer to discuss if your floors are up to par for air caster technology to function efficiently.

Most plant air systems and adequate pressure (usually over 80 psi) for air caster technology. However, make sure the airflow is strong enough for the equipment you’re looking into. The required air consumption for the efficient operation of air casters is 3 SCFM per foot of air bearing perimeter.

Airfloat Air Skids range in size from 10 inches to 54 inches, with single-skid capacity from 500 pounds to 60,000 pounds per skid. Custom sizes are also available.

Air Platform with Roll Cradle

Air Platform with Roll Cradle