The wheel has been used for transportation and load movement for thousands of years, and for good reason; it’s simple, easy to deploy and highly adaptable. But wheels have limitations. While they’re great for moving a few hundred – or even a few thousand – pounds, things quickly become more complicated when loads exceed 5 tons, 50 tons or more.

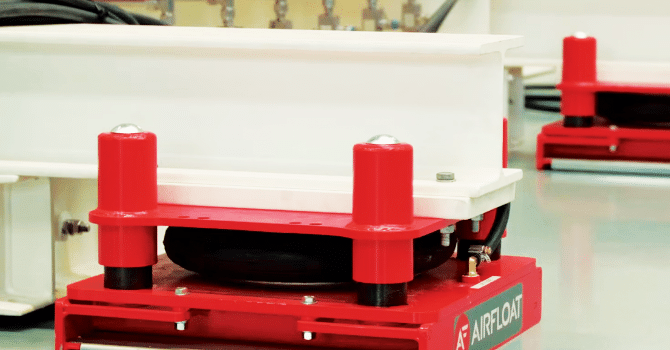

The air caster is the first real alternative to the wheel to come along in millennia. Conceived in the early ‘60s by a research & development lab at General Motors, air casters are ideally suited for heavy load movement and positioning.

True Omnidirectional Movement

Unlike wheels, air bearings move with equal ease in any lateral direction, allowing them to easily maneuver around corners or in cramped spaces.

Near Frictionless Movement

Because air casters float on a thin film of air, they’re virtually frictionless, allowing a 1,000-lb. load to be pushed or pulled with only about a pound of force. That’s 10 times more efficient than traditional wheels or casters.

Easier on Floors

Because of their greater surface area, air casters disperse weight far better than wheels, reducing point loading. And because they literally float a millimeter or two above the ground, they greatly reduce floor wear and tear.

But like wheels, air casters also have limitations. First, they require a relatively smooth, flat and level floor to operate at optimal efficiency. They also need a reliable supply of compressed air. The advantages offered by air casters, however, far outweigh these modest limitations.

Are air casters the right solution for your material handling challenge? Contact Airfloat today to speak with an application engineer.