THE CREATORS OF

Air Caster Technology

Tech Overview

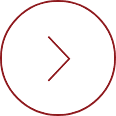

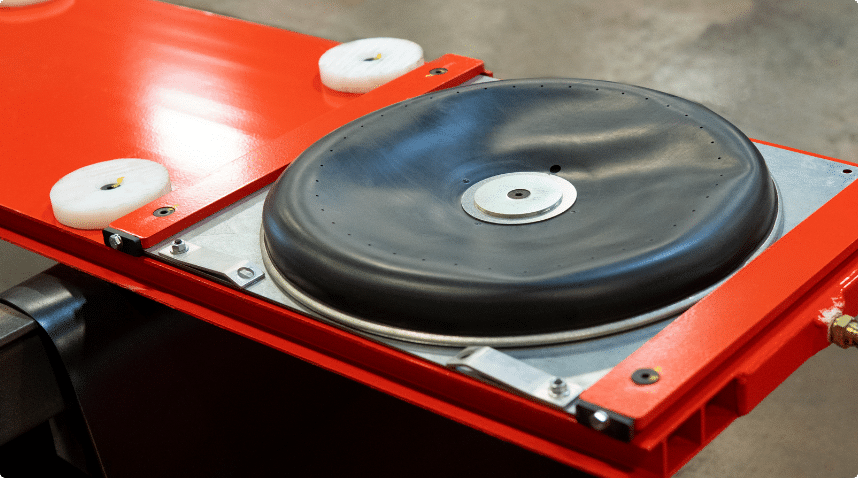

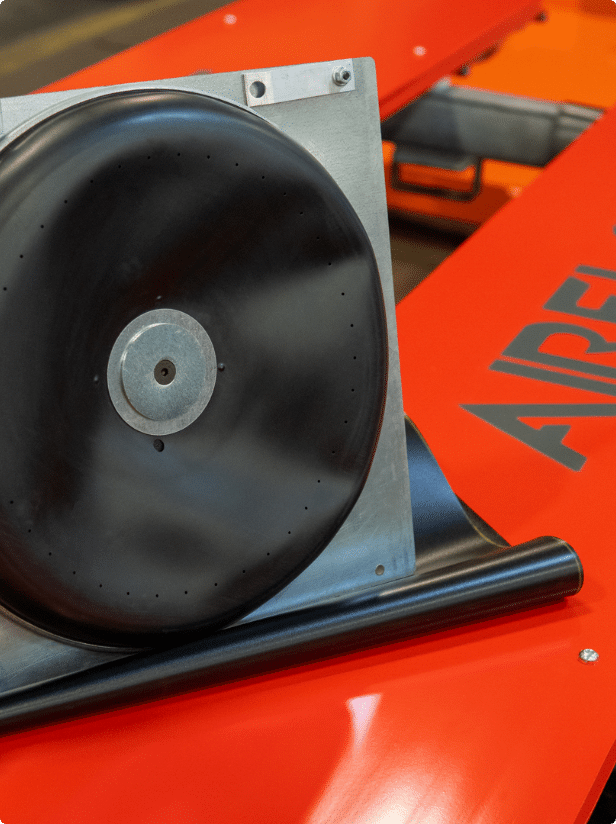

An air caster is a pneumatic device that forms a lubricating film of air between the load and floor surface, similar to that of a hovercraft or an air hockey table. A flexible, wear-resistant urethane diaphragm is inflated by compressed air, forming a seal with the floor and lifting the structure off its rest pads. Air is then squeezed between the floor and the diaphragm, creating a thin film of air and allowing the load to float.

THE MOST DURABLE

HEAVY LOAD TRANSPORT

ON THE MARKET

HEAVY LOAD TRANSPORT

ON THE MARKET

THE WHEEL 2.0™

The wheel has been used for transportation and load movement for thousands of years, and for good reason; it’s simple, easy to deploy and highly adaptable. But wheels have limitations.

THE MOST ENERGY

EFFICIENT PRODUCTION

LINE TRANSPORTER

EFFICIENT PRODUCTION

LINE TRANSPORTER

AIR REQUIREMENTS

Most plant air systems are suitable for air bearing (or “air caster”) equipment. The amount of air flow required to operate an air caster depends on three variables.

INDUSTRY-LEADING

FLOORING AND SURFACE

ADAPTABILITY

FLOORING AND SURFACE

ADAPTABILITY

FLOORING SPECIFICATIONS

Airfloat air bearings, like all air-film equipment, require a suitable floor to work properly. This does not mean that your floor must be smooth as glass to achieve floatation.

FROM AIRFLOAT CUSTOMERS