THE SITUATION

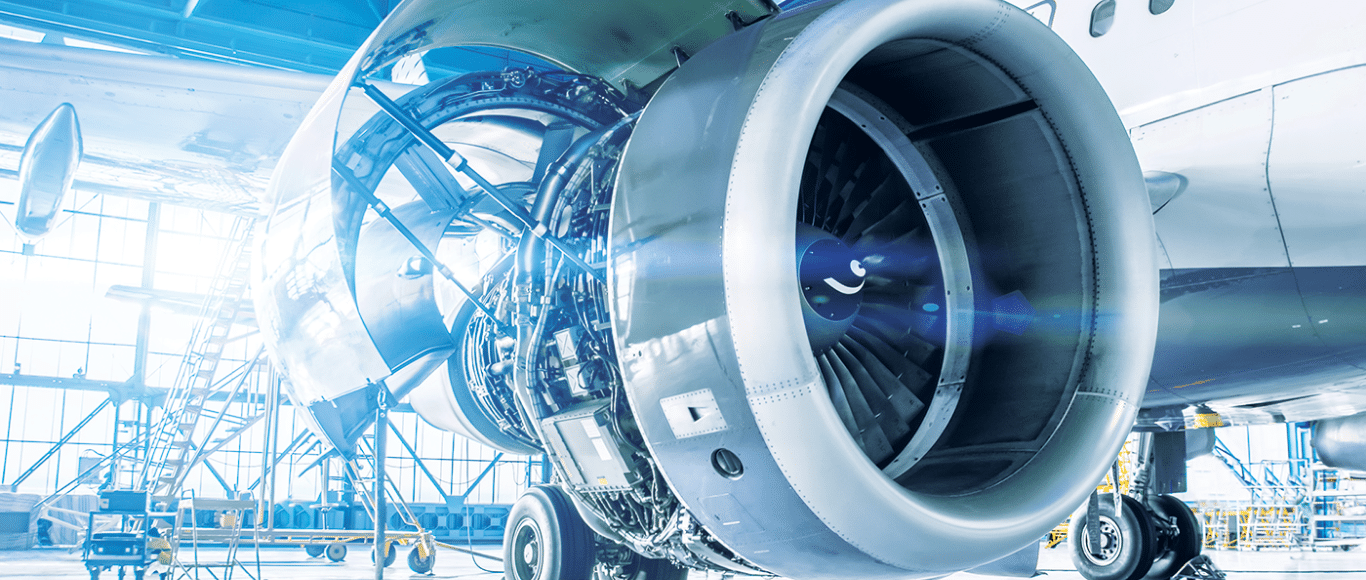

The manufacture of aircraft has changed enormously in recent years. The main difference: Instead of being assembled in one spot, most aircraft today are built on moving assembly lines similar to those used by automakers. Most aerospace manufacturers, however, still rely on outdated wheeled transporters and overhead cranes to move aircraft through the various manufacturing stages.

Bombardier Aerospace, the third-largest airplane manufacturer in the world, wanted to modernize and streamline work at its Toronto, Canada, factory. The company turned to Airfloat, with its decades of aerospace experience, for a custom air caster solution.