Offshore Oil

Drilling

CASE STUDY

THE SITUATION

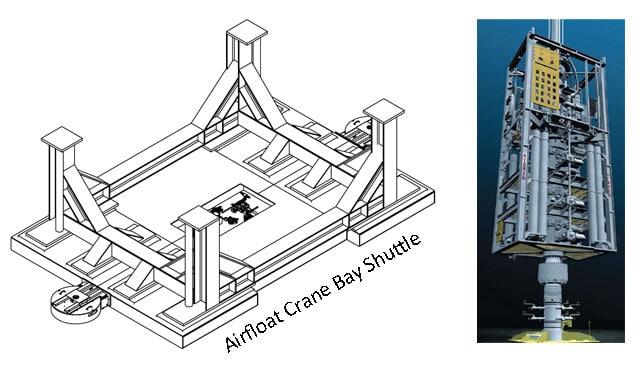

A maker of offshore drilling equipment faced a daunting challenge at one of its Houston-area manufacturing facilities: moving a 20-ft.-high, 300-ton blowout preventer (BOP) from an existing assembly bay to a brand-new bay in a recently added building extension. A BOP is a complex mechanism that sits on the seafloor atop a well head, serving as the last line of defense if something goes wrong. After considering several options, the company ultimately partnered with Airfloat to create an air-riding crane bay shuttle system that would “float” the BOP on a thin film of compressed air.

THE SOLUTION

The Result

A test stand with support columns is bolted atop the Airfloat transfer car to securely hold the sensitive load. Then the blowout preventer is lifted onto the stand by overhead crane. Air to the system is turned on, allowing the load to float virtually friction-free. The load is driven to the destination bay at a top speed of 10 feet per minute. Lastly, the BOP is removed from the transfer car by crane.