THE SITUATION

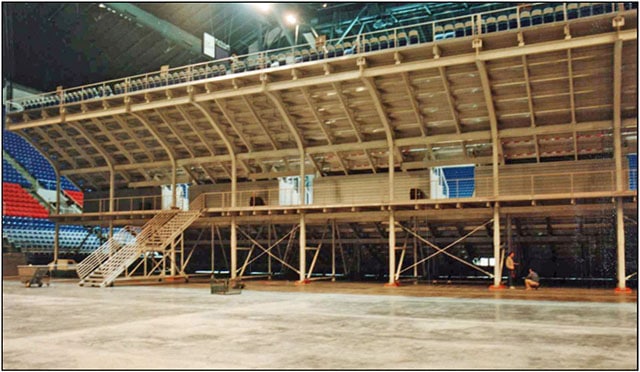

A sports stadium needed a way to quickly and easily reconfigure its four grandstand sections to accommodate the viewing of different sports like football and baseball. Each grandstand section holds 7,000 seats and weighs approximately 3.5 million pounds.