Air Bearings: Ideal for Explosive Environments, Autoclaves

A new white paper that describes the top 14 applications of air bearing (or “air caster”) technology has been published to airfloat.com. The white paper is based on Airfloat’s nearly 50 years of experience in the field. Below is an excerpt:

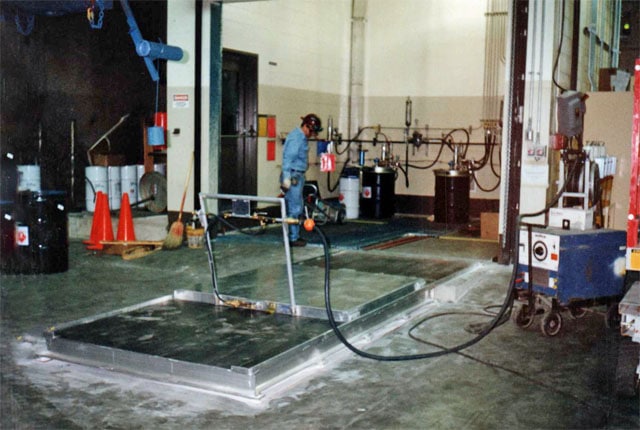

Paint or Hazardous Areas

The need for costly explosion-proof trucks has been eliminated in some applications by using air bearing platforms. The platforms are equipped with aluminum rest bars to prevent sparking against the concrete surface.

In such applications, loads are normally less than 8,000 lbs. and can be moved manually by Airfloat equipment. Heavier loads can be moved with an added pneumatic power tugger.

Autoclaves

The conventional method of autoclave loading uses wheeled dollies and tracks. However, with increasing autoclave capacity and larger loads, these dollies require more and more force for movement. Additionally, the elevated temperatures of the autoclaves also tend to shorten wheel and wheel‐bearing life.

A typical design approach for autoclave loading using Airfloat technology would include an inverted U‐shaped autoclave pallet. A low profile air bearing transporter with auxiliary lift would move under the pallet, lift and move it into the autoclave. The transporter would then be withdrawn. Note: Maximum temperature for Airfloat diaphragms is 140° F (60° C).

To download the white paper, click here and fill out the form on the right-hand column.